The congenital malformations, arthritis, osteoporosis, traumatic accidents, spinal deformities, among others are the basis for need bone and cartilage replacements. The chronic pain, inflammation or discomfort of these diseases translates into a significant impact on patients’ and hospital treatments costs. There is yet no solution that meets the structural and functional requirements of definitive implants. In the case of trauma, for example, treatment often consists of bone joining or even implants in a nonpermanent situation, that is, requiring more than one surgical intervention which causes pain and discomfort to the patient besides the costs involved. Therefore, the development of low cost, durable, compatible and functional solutions is needed. Namely bone substitutes that can be perfectly integrated, morphologically and anatomically biocompatible, with complex structure and a material that mimics native bone and encourages cell migration, proliferation and differentiation.

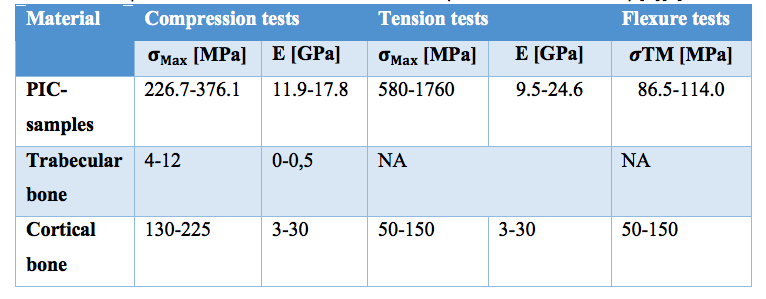

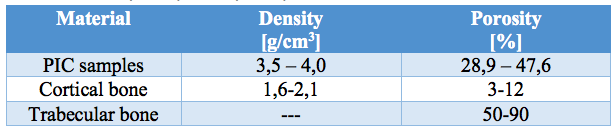

Ideally a bone substitute has original three-dimensional anatomical shape the trabecular zone is dense and has Young’s modulus in the range of 0.01-0.5 GPa and compressive strength values of 4-12 MPa while the cortical region is porous with compressive strength values in the range 130-225 MPa and modulus Young from 3-30GPa.

The development of bone implants represents an area of medicine attracting growing interest in recent years. Most used implants are made of noble metals such as titanium. This material, although with good biocompatibility, strength and durability characteristics, faces often body rejection problems. To avoid that, the metal is coated with a biocompatible ceramic material (zirconia, hydroxyapatite, etc.). Despite their good performance, titanium implants have a much higher Young’s modulus than bone, which leads to localized stress phenomena, increase of osteoblast activity and may lead to periprosthetic osteolysis and consequent implant failure.

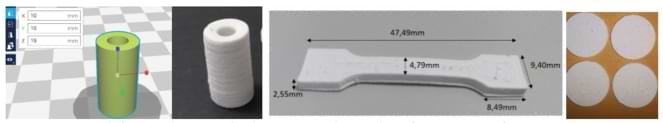

The 3D printing techniques provided opportunities for the development of customized pieces. Ceramics, plastics and metals are all possible to printing in three dimensions by additive or subtractive techniques. In particular subtractive techniques are already used to perform ceramic teeth for dentistry. A piece of dense ceramic material is mechanically dug until the desired form is obtained. However, the dense ceramic implant behaves most likely the metal implants as it doesn’t allow the body fluids to flow through it. Compared to other techniques, the great advantage of pastes extrusion technique is the facility to mimic the graded porosity of implants while a specific design according to patient needs, reaching the mechanical properties close to those of the native bone, as well as their adequate, porosity, permeability to cells, biocompatibility and durability.

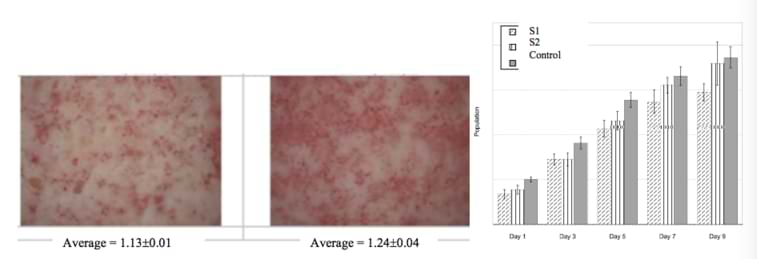

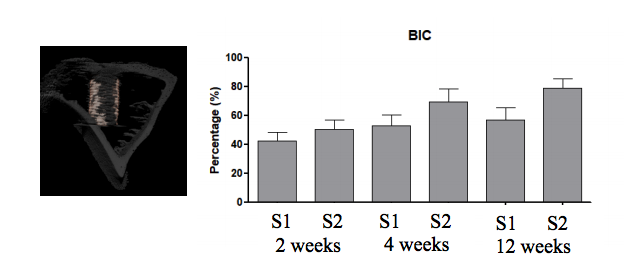

The goal of the NOVA researchers is to develop low cost production ceramic implants, permanent, conformal and compatible with the specific needs of patients, mimicking resistance and bioactivity. This approach was achieved in preliminary results focused in 3D printed pieces of ceramics powders, achieving mechanical properties in the range of cortical bone, the most demanding in terms of mechanical strength. Indeed, the cortical mechanical resistance values were achieved just printing pieces layer-by-layer with pastes made with inorganic and organic compounds. The required biocompatibility and osteointegration was also tested in-vivo.